In 2020, the U.S. Bureau of Labor Statistics reported that 142 fatalities and 17% of all non-fatal workplace injuries were caused by employees being struck, caught or crushed by objects or equipment. In addition, compliance with the various OSHA machine guarding standards, which will prevent many of these incidents, is one of the top 10 cited OSHA regulations in general industry. Not only can this non-compliance result in debilitating amputations, crush injuries or death, it creates unwarranted legal liabilities and poor employee morale during a time when retention is so important.

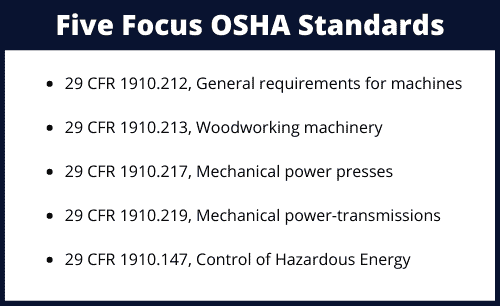

Due to the prevalence of machine related injuries, OSHA created a National Emphasis Program (NEP) to help reduce amputations in the manufacturing sector. This program is being used to prioritize OSHA resources and target employers for inspections. While OSHA has five focus standards that they are looking at to help reduce amputation injuries, there are many others that employers need to implement.

To comply with these regulations, employers must first understand the forms of hazardous energy that exist in their workplaces and which tasks could result in injury if that energy is not properly controlled. This may sound simple but it requires significant knowledge and expertise to ensure you are protecting employees from serious injury and avoiding OSHA citations or possibly bad press.

To comply with these regulations, employers must first understand the forms of hazardous energy that exist in their workplaces and which tasks could result in injury if that energy is not properly controlled. This may sound simple but it requires significant knowledge and expertise to ensure you are protecting employees from serious injury and avoiding OSHA citations or possibly bad press.

For tasks such as cleaning, maintenance, or service work, protection is often accomplished through an effective control of hazardous energy (or lockout/tagout-LOTO) program as described in 29 CFR 1910.147. This requires the authorized employee to deenergize the equipment following an equipment-specific procedure before performing tasks. While many organizations spend a lot of time developing these equipment LOTO procedures, gaps arise when no one is checking to make sure they are used properly. An effective LOTO program must include effective training and a strong observation program where someone of authority observes each person at least annually performing each procedure to ensure they are following it carefully and that procedures are updated as changes occur.

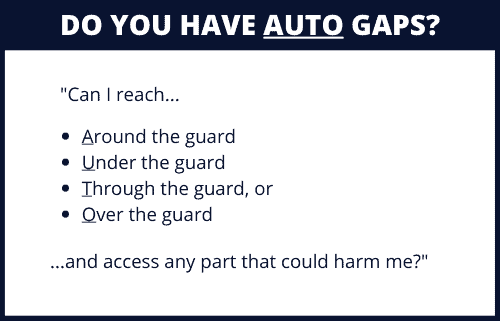

But what is often more difficult for organizations, is staying on top of the various machine guarding standards and technologies to ensure that proper safe guards are in place for equipment. Any equipment that has nipping, shearing, pressing, punching, bending, compressing, or power transmission components or parts that get hot or cold or create flying debris need machine safeguarding in place to meet these standards. If you are not sure if your equipment is covered, walk out on the manufacturing floor and Look for AUTO Gaps. If the answer to any of these questions is yes or the guard is on the ground, then you may want to focus on machine guarding. OSHA expects that thorough machine guarding assessments are done to ensure appropriate guards, alternative protective measures and/or standard operating procedures in place. Acceptable alternative measures include specially designed tools, remote devices, interlocked barrier guards, local disconnects, or control switches which are under the exclusive control of the employee working. The combination of these three options must provide equivalent protection to equipment de-energization so that no employee is ever harmed and you can pass an OSHA inspection.

But what is often more difficult for organizations, is staying on top of the various machine guarding standards and technologies to ensure that proper safe guards are in place for equipment. Any equipment that has nipping, shearing, pressing, punching, bending, compressing, or power transmission components or parts that get hot or cold or create flying debris need machine safeguarding in place to meet these standards. If you are not sure if your equipment is covered, walk out on the manufacturing floor and Look for AUTO Gaps. If the answer to any of these questions is yes or the guard is on the ground, then you may want to focus on machine guarding. OSHA expects that thorough machine guarding assessments are done to ensure appropriate guards, alternative protective measures and/or standard operating procedures in place. Acceptable alternative measures include specially designed tools, remote devices, interlocked barrier guards, local disconnects, or control switches which are under the exclusive control of the employee working. The combination of these three options must provide equivalent protection to equipment de-energization so that no employee is ever harmed and you can pass an OSHA inspection.

This can be done by conducting thorough Job Hazard Analyses (JHAs) or focusing on a detailed machine guarding assessment if you are not ready for a robust JHA program. JHAs are more comprehensive and often identify risks that may only be known from the employee’s perspective. By asking “what do they do if something gets stuck” or what tasks require them to lockout the equipment, you will often identify guarding issues or gaps that occur during abnormal conditions or non-routine tasks. It is well known that a large portion of serious and fatal incidents occur during these conditions. Regardless of how you conduct the machine guarding assessments, it is important to use personnel who can review and understand the state of the current guarding in place and determine if it is adequate to meet OSHA regulations and most importantly protect your employees from injury.

The best equipment safeguards include physical guards or devices that prevent access to hazardous components. This may include a variety of fixed or flexible physical guards as well as interlocking devices and various electronic presence or pressure sensing devices. It may also be as simple as a two-hand operating device. Often a combination of these controls is necessary to prevent injuries and meet the standards.

CMI has seasoned professionals who routinely help organizations of all sizes to develop cost effective programs that reduce machine related risks. Please contact us for a free phone consult if you have questions related to energy control or equipment safeguarding.

Written by Rebecca Caffrey, GSP, Senior Health and Safety Specialist